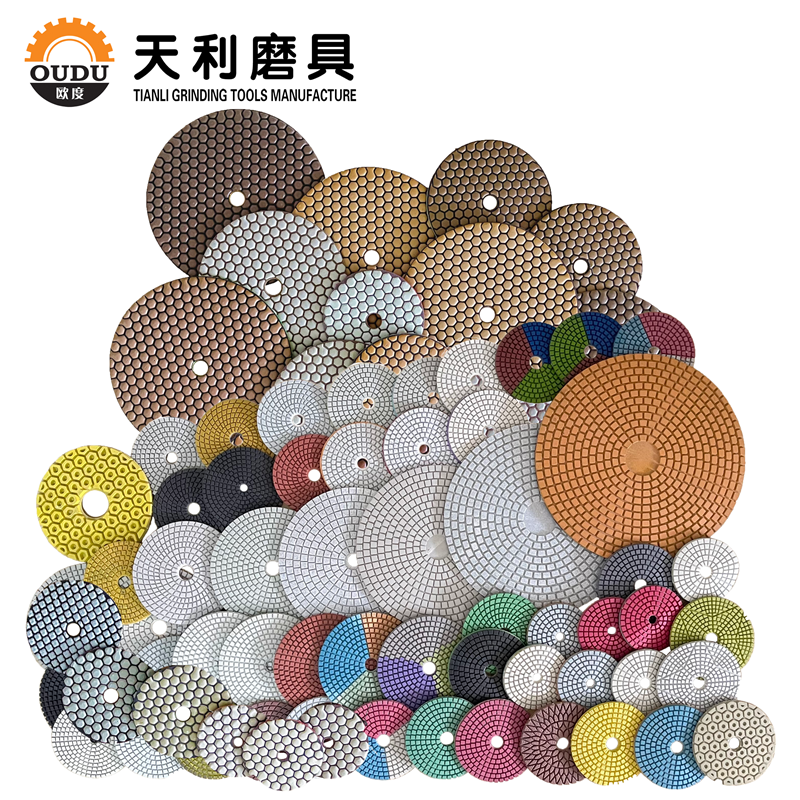

When grinding stone, will certainly use abrasives and abrasives, encounter different stone, the choice of abrasives are not the same. Today, Quanzhou Tianli Co., Ltd. to talk about the choice of grinding tools and abrasives when grinding stone.

1. Diamond grinding disc

Diamond grinding disc is made by sintering diamond abrasive. Because it is not widely used in our industry, the numbering is cumbersome, so it is omitted here and will not be detailed.

Advantages: suitable for most stone grinding machine; It IS AN IDEAL GRINDING TOOL WITH fast grinding speed, good wear resistance, strong grain holding force, high grinding efficiency and low grinding cost.

Disadvantages: easy to chew the stone, bring trouble to the follow-up process; The subsequent numbering of millstones is tedious.

2. Bitter soil, resin grinding stone (block)

Bitter earth, resin grindstone (block) is made of bitter earth, resin and other materials as adhesive filling materials, and the grinding material is cast and baked. Widely used in stone processing line, also used by many professional stone renovation enterprises. There are two kinds of numbering, one is by item number, the other is number number:

Number of items: 36, 60, 120, 240, 400, 800.

Number: 1, 2, 3, 4, 5, 0 (polishing number).

Advantages: High grinding quality and stability; Good adaptability, strong controllability; Good things are cheap.

Shortcomings: domestic grinding stone (block) polishing number (0) quality is not stable, poor light; Imported grinding stone (block) general price on the high side (such as: 5EX, 10LG).

3. Stone renovation piece, water grinding piece

Stone refurbished piece, water grinding piece because of the abrasive containing diamond micro powder, so it is also known as diamond water grinding piece, we often refer to stone refurbished piece as hard piece, and the water grinding piece as soft piece. (Water mill is widely used in edge, Angle, special-shaped grinding treatment.)

Because it is easy to carry and use, it is favored by most stone renovation enterprises. It is sorted into two kinds of international number and domestic number:

The international numbers are 30#, 50#, 100#, 200#, 400#, 800#, 1500#, and 3000#.

The domestic number is; 30#, 50#, 150#, 300#, 500#, 1000#, 2000#, 3000#.

From the above data, it can be seen that the number of the next mesh is basically 2 times of the number of the last mesh. Theoretically, this formula design can just ensure that the next blade can eliminate the scratches of the upper blade.

Advantages: strong practicability, widely used; Easy to carry and use.

Drawback: The stone material surface that has been ground shows dry feeling (fade, hair is white).

To sum up, it is not difficult to see that in addition to the choice of machinery and equipment, the choice of abrasive tools and abrasive materials is also crucial, which directly affects the output of the enterprise, affects the income of the enterprise, affects the income of the individual, and affects every one of us. Therefore, we suggest that qualified enterprises should choose more cost-effective abrasive tools and abrasives to reduce costs, improve output and improve earnings.

Read this article, you must have a further understanding of the choice of abrasive tools. Now also should know how to choose it, if this article can not help you, want to know more, welcome you to Tianli abrasive tools Co., LTD. Consultation.

Post time: Dec-15-2022